Surface Enhancement for PCR Plastics Market Set to Surge to USD 4.82 Billion by 2036

surface enhancement technologies for PCR plastics market revenue is projected to total USD 1,360 million in 2026, increasing to USD 4,820 million by 2036.

NEWARK, DE, UNITED STATES, February 16, 2026 /EINPresswire.com/ -- The global surface enhancement technologies for PCR plastics market is entering a period of rapid industrialization. Valuation is projected to reach USD 1,360 million in 2026 and is expected to soar to USD 4,820 million by 2036, expanding at a robust 13.5% CAGR.

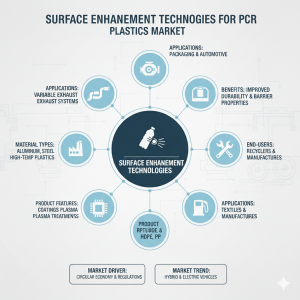

According to Future Market Insights (FMI), this growth is driven by a shift from performance-limiting generic coatings to chemically tailored systems that bond molecularly with post-consumer recycled (PCR) substrates, bridging the "quality gap" between recycled and virgin materials.

Market snapshot: global Surface Enhancement Technologies for PCR Plastics Market 2026 - 2036

• Market Size (2026): Estimated at USD 1,360 million.

• Market Size (2036): Projected to reach USD 4,820 million.

• CAGR (2026-2036): 13.5%.

• Leading Technology: Coatings & Surface Texturing holds a dominant 50% market share.

• Leading Application: Cosmetic & Premium Packaging commands a 25% value share.

• Key Growth Region: India is the fastest-growing market at a 15.6% CAGR.

• Major Players: AkzoNobel, BASF, PPG Industries, Sherwin-Williams, DIC Corporation, and Sidel.

Request For Sample Report | Customize Report | Purchase Full Report

https://www.futuremarketinsights.com/reports/sample/rep-gb-32002

Key Market Trends & Innovations

1. High-Tech Safety Standardization

Rather than waiting for legislative mandates, the industry is pivoting toward voluntary safety standards. The CosPaTox guideline (April 2024) has become a defensible inflection point, providing a structured safety assessment for recycled PE/PP/LDPE in cosmetic and home care packaging. This has catalyzed R&D into functional coatings that reduce risk from contaminants.

2. Advanced Curing & Plasma Industrialization

The 2026-2027 period is defined by the rise of low-temperature plasma and UV-LED curing. These processes functionalize surfaces without heat-degrading the underlying recycled polymer—a breakthrough for thin-walled electronics and packaging.

• Sidel’s Actis plasma coating recently received APR Design® for Recyclability Recognition, proving that high-barrier plasma layers can coexist with circular recycling loops.

3. "Digital Surface Twins" and Customization

Technical innovation is moving toward digital integration. BASF’s "Texture-on-Demand" laser system, launched in 2026, allows manufacturers to digitally vary textures (from linen to leather grain) on a single mold, enabling mass customization for PCR parts without the cost of new tooling.

Competitive Landscape

The market is shifting from standalone chemical suppliers to Integrated Surface Solution Providers. In August 2025, DIC Corporation established a landmark facility in Indonesia dedicated to sustainable food-contact coatings, emphasizing the shift toward regional, high-compliance production.

Major players are also forming Surface Enhancement Alliances—three-way development agreements between carmakers, PCR compounders, and coating firms to share the costs of qualifying new sustainable material systems.

Key Players Profiled:

• AkzoNobel N.V.

• BASF SE (Coatings Division)

• PPG Industries, Inc.

• The Sherwin-Williams Company

• DIC Corporation

• Sidel (Plasma Technologies)

FAQ

What is the growth outlook for the global PCR plastics surface enhancement market?

The market is projected to grow from USD 1,360 million in 2026 to USD 4,820 million by 2036, representing a robust 13.5% CAGR.

What are the primary drivers for adopting surface enhancement on recycled plastics?

Growth is driven by the technical need to bridge the quality gap between PCR and virgin plastics, specifically addressing issues like inconsistent pigmentation, reduced surface energy, and lower abrasion resistance.

Which technology segment currently dominates the market?

Coatings & Surface Texturing holds a leading 50% share, as these versatile methods effectively manage both the aesthetics and the functional protection of recycled materials.

Which region is expected to experience the fastest growth through 2036?

India is the fastest-growing market with a 15.6% CAGR, fueled by an explosive boom in domestic electronics manufacturing and mass-market packaging sectors.

Who are the key industry players driving innovation in this space?

Major players include global chemical leaders like AkzoNobel, BASF SE, PPG Industries, and Sherwin-Williams, alongside specialist firms like Plasmatreat GmbH.

Similar Industry Reports

Fire Safe PCR Plastics for Electric Vehicles Market

https://www.futuremarketinsights.com/reports/fire-safe-pcr-plastics-for-electric-vehicles-market

Impact-Modified PCR Plastics for Packaging Market

https://www.futuremarketinsights.com/reports/impact-modified-pcr-plastics-for-packaging-market

Flame-Retardant PCR Plastics for Consumer Electronics Market

https://www.futuremarketinsights.com/reports/flame-retardant-pcr-plastics-for-consumer-electronics-market

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.